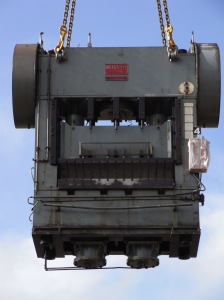

We have recently completed a full press inspection report and removal of a Bliss Welded Products Model S2-250-84-48 (weight 35 tons) and a Bliss Welded Products Model S2-350-84-48 (weight 44 tons).

We removed all power, air supply, clutch and brakes units, guarding and other equipment before the lift and managed cranes and transport.

A challenging site required the removal of the roof to allow for the presses to be lifted out with a 130 ton crane with a 20 ton Frana assisting in an adjacent yard to load on a flat deck for interstate transport.

The 250 ton Bliss Welded Products press was transported interstate and the 350 ton Bliss Welded Products press was transported to the Revro factory to repair the Bliss clutch and brake unit, increase shut height (daylight) by 5″ and manufacture new tie rods to accommodate longer tie rods (to allow common dies to be used during manufacturing).

As a separate project we removed a Wilkins & Mitchell 150 Ton 2 Point Gear Eccentric Press.